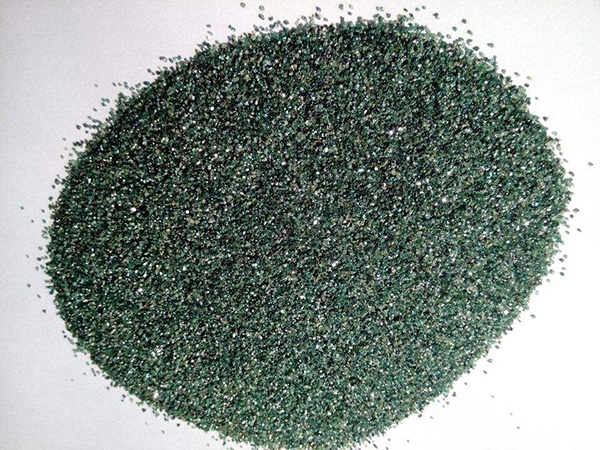

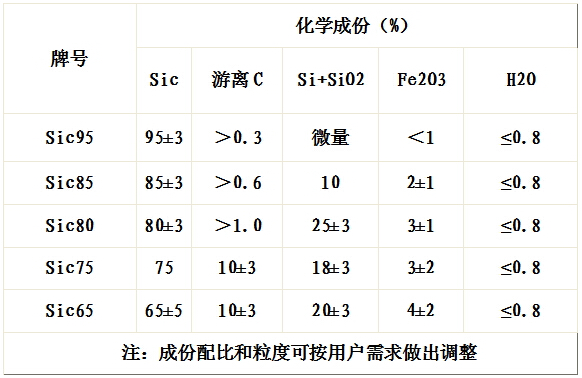

Silicon Carbide is made of quartz sand and stone tar as raw materials in electric resistance furnace, also known as carbon silica. It is widely used in high-tech refractory materials. It is a kind of economical one. The silicon carbide produced in China is black and green.

Due to its stable chemical properties, high thermal conductivity, low thermal expansion coefficient and good wear resistance, Silicon Carbide has many uses in addition to abrasives:

1. Low-grade Silicon Carbide (85% silicon) is an excellent deoxidizer, which can speed up steel making and control chemical composition and improve steel quality.

2. Silicon Carbide is also used to make silicon carbide rods for electric heating elements.

Silicon Carbide Applications (Four Major Areas)

1. Functional ceramics 2. Refractory materials 3. Abrasives (used for grinding tools, grinding wheels, oilstones, sand tiles, etc.) 4. Metallurgical raw materials (deoxidizers and high temperature resistant materials)

Silicon Carbide Deoxidizer is a new type of strong composite deoxidizer, which replaces the traditional silicon powder carbon powder for deoxidation. Compared with the original process, the physical and chemical properties are more stable, the deoxidation effect is good, the deoxidation time is short, energy is saved, and the refining is improved. Steel efficiency, improve the quality of steel, reduce the consumption of raw and auxiliary materials, reduce environmental pollution, improve working conditions, and improve energy and economic benefits of electric furnaces.

- Prev:None;

- Next:Ferro Silicon Aluminum Alloy

-

Deoxidizer

-

Ferro Silicon

-

Silicon Carbon Alloy

-

Cored Wire

-

High Carbon Ferro Silicon

-

Silicon Briquette

-

FeTi Cored Wire

-

Silicon Metal Powder

-

Seamless Metal Calcium Cored Wire

-

Solid Compound Calcium Cored Wire

-

High Carbon Silicon Briquette

-

Carbon Additive

-

Ferro Silicon Powder

-

Silicon Calcium Cored Wire

-

Silicon Calcium Composite Deoxidizer

-

Silicon Carbon Alloy Powder

-

Ferro Silicon Briquette

-

CaFe Cored Wire

-

Silicon Aluminum Composite Deoxidizer

-

Silicon Carbon Briquette

-

Ferro silicon magnesium

-

Sulfur Cord Wire

-

Silicon Carbide Deoxidizer

-

Aluminum Cored Wire

-

Silicon Barium Cored Wire

-

Composite Deoxidizer

-

Silicon Barium Calcium Cored Wire

-

Silicon Calcium Manganese Deoxidizer

-

Silicon Barium Alloy

-

Silicon Aluminum Calcium Deoxidizer

-

Calcium Metal Cored Wire

-

Silicon Calcium Barium Alloy

-

Ferro Silicon Aluminum Alloy

-

Silicon Carbon Alloy

-

Silicon Calcium Alloy

-

Green Silicon Carbide

-

Silicon Aluminum Alloy Deoxidizer

-

Silicon Aluminum Manganese Alloy

-

Black Silicon Carbide

-

Manganese metal ingot

-

Silicon metal

-

Manganese flake

-

Low Carbon Silicon

-

Calcium Aluminate

+86-13460933678

+86-13460933678